Classification and Application Industries of Mesoporous Materials

2025-04-05

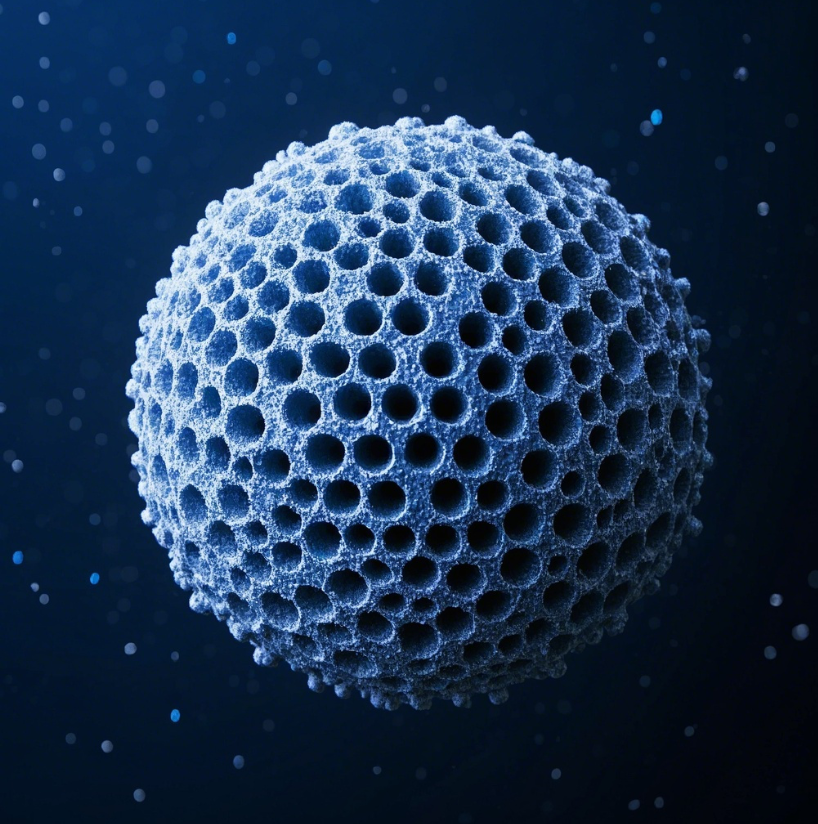

Mesoporous materials can be classified according to different criteria. Common classification methods are as follows: I. Classification by Chemical Composition 1.1 Silica - based Mesoporous MaterialsThis is the earliest and most widely studied type of mesoporous materials. It mainly consists of silica and has a high specific surface area, regular pore structure, and good chemical stability. Typical representatives include MCM - 41 and SBA - 15. MCM - 41 has a hexagonal ordered pore structure with a pore size generally between 2 - 10 nm. SBA - 15 has a thicker pore wall, a larger pore size in the range of 5 - 30 nm, and better hydrothermal stability than MCM - 41.1.2 Metal Oxide Mesoporous MaterialsThis type includes mesoporous materials composed of various metal oxides such as alumina, titania, and zinc oxide. They have unique physical and chemical properties and are important in fields such as catalysis and sensing. For example, mesoporous alumina has a high specific surface area and good thermal stability and is commonly used as a catalyst support. Mesoporous titania, due to its photocatalytic activity, has attracted attention in wastewater treatment and photocatalytic hydrogen production. 1.3 Carbon - based Mesoporous MaterialsThese materials have a high specific surface area, good electrical conductivity, and chemical stability. Common preparation methods use phenolic resin, sucrose, etc. as carbon sources and are prepared by the template method. Mesoporous carbon materials exhibit excellent performance in supercapacitors, lithium - ion battery electrode materials, and adsorption and separation.Carbon - based mesoporous materials are applied in the field of electrochemical catalysis. 1.4 Metal - Organic Framework (MOF) Mesoporous MaterialsThese are porous materials formed by the self - assembly of metal ions or metal clusters and organic ligands through coordination bonds to form a periodic network structure. MOF materials have an extremely high specific surface area and a tunable pore structure. The pore size and shape can be precisely designed by selecting different metal ions and organic ligands. They have broad application prospects in gas storage and separation, catalysis, drug delivery, etc.Morphology of Metal - Organic Framework (MOF) Mesoporous Materials II. Classification by Pore Structure 2.1 Ordered Mesoporous MaterialsThe pore channels are arranged regularly and orderly, with a high degree of periodicity and symmetry. For example, MCM - 41 mentioned above is arranged in a hexagonal order, and there is also cubic - phase KIT - 6, etc. The regular pore structure of this type of material is beneficial to the transport and diffusion of substances, and it shows excellent performance in applications such as catalysis and adsorption. Schematic Diagram of Single - Micelle Directed Synthesis of Ordered Mesoporous Materials 2.2 Disordered Mesoporous MaterialsThe pore structure is relatively irregular, without obvious periodicity and symmetry. Although the pore order degree is not as good as that of ordered mesoporous materials, in some applications, the disordered mesoporous structure can also provide unique performance advantages. For example, in some adsorption systems where the requirements for pore connectivity are high and the requirements for pore regularity are relatively low, disordered mesoporous materials may have better adsorption kinetics performance.Synthesis of Disordered Mesoporous Silica III. Application Industries and Fields of Mesoporous Materials 3.1 Catalysis Fielda. Petrochemical IndustryIn the process of oil refining, mesoporous materials, as catalysts or catalyst supports, contribute to reactions such as oil cracking and reforming. Their large specific surface area and appropriate pore structure can highly disperse the active components, improve the catalytic efficiency, reduce the reaction temperature and pressure, and reduce energy consumption and equipment wear. For example, in the heavy - oil cracking reaction, mesoporous molecular sieve catalysts can convert heavy - oil macromolecules into light - oil products, improving the quality and yield of oil products. b. Fine Chemical IndustryFor the synthesis of fine chemicals, such as the production of pharmaceutical intermediates, spices, additives, etc., mesoporous material catalysts can achieve highly selective catalytic reactions. By designing the pore size and surface properties, specific reactants can enter the pores and react at the active sites, suppressing side reactions and improving the yield and purity of the target product. 3.2 Adsorption and Separation Field c. Gas Adsorption and StorageMesoporous materials can be used for the adsorption and storage of gases such as hydrogen and methane. Their abundant pore structures provide a large number of adsorption sites, enabling efficient gas adsorption and reversible desorption under relatively mild conditions, which is expected to solve the problems of storage and transportation of clean energy such as hydrogen. In addition, in air purification, mesoporous materials can selectively adsorb harmful gases such as sulfur dioxide, nitrogen oxides, and volatile organic compounds (VOCs), improving air quality.Gas Adsorption Capacity of New Mesoporous Materialsd. Liquid SeparationIn water treatment, mesoporous materials can be used to remove heavy metal ions and organic pollutants in water. Their pore size can be precisely controlled to screen molecules and ions of different sizes. For example, mesoporous activated carbon has a good adsorption performance for organic pollutants such as dyes and pesticides in water. Mesoporous ceramic membranes can be used in processes such as ultrafiltration and microfiltration to achieve solid - liquid separation and the separation of substances with different molecular weights.Method and Process for Synthesizing Mesoporous Titania Materials in Aqueous Phase 3.3 Energy Fielde. Battery MaterialsIn lithium - ion batteries, mesoporous - structured electrode materials can provide more lithium - ion insertion/extraction channels, shorten the ion diffusion distance, and improve the charge - discharge efficiency and cycle stability of the battery. For example, mesoporous titania, as a negative electrode material, has a high specific capacity and good rate performance. Mesoporous carbon materials can be used to prepare high - performance supercapacitor electrodes. Their large specific surface area and developed pore structure help to quickly store and release charges, improving the energy density and power density of supercapacitors.Mesoporous Carbon Electrode for Carbon - based Perovskite Solar Cells f. Solar Energy UtilizationMesoporous semiconductor materials play an important role in solar cells and photocatalytic water - splitting for hydrogen production. For example, mesoporous titania thin films are key photoanode materials in dye - sensitized solar cells. Their high specific surface area can load more dye molecules, enhancing the absorption of sunlight and the photoelectric conversion efficiency. In photocatalytic water - splitting for hydrogen production, the mesoporous structure helps to improve the light absorption and utilization efficiency of photocatalysts, promote the separation and transfer of photogenerated carriers, and thus increase the hydrogen production efficiency.Application of Mesoporous Semiconductor Materials in Solar Cells and Photocatalytic Water - splitting for Hydrogen Production 3.4 Biomedical Field g. Drug CarriersMesoporous materials have good biocompatibility and a large pore volume, enabling them to load a large number of drug molecules. By modifying the pore surface, targeted drug delivery and controlled release can be achieved. For example, loading anti - cancer drugs in mesoporous silica nanoparticles and modifying them with ligands targeting tumor cells can enable the drugs to accurately accumulate in tumor tissues, reducing the toxic side effects on normal tissues. At the same time, by adjusting the pore structure and surface properties of mesoporous materials, the drug release rate can be controlled to achieve long - acting sustained - release treatment.Application of Mesoporous Silica in Drug Carriers h. BiosensorsUsing the high specific surface area and good adsorption properties of mesoporous materials, biological recognition molecules (such as enzymes, antibodies, nucleic acids, etc.) are immobilized to prepare biosensors. Mesoporous materials can increase the loading amount of biological recognition molecules, improving the sensitivity and detection limit of the sensor. For example, the glucose sensor based on mesoporous carbon materials can quickly and accurately detect the glucose content in blood, providing convenience for blood - glucose monitoring of diabetic patients.Application Principle of Mesoporous Silica in the Biomedical Field 3.5 Electronic Information Field i. Microelectronic DevicesIn semiconductor chip manufacturing, mesoporous materials can be used to prepare low - dielectric - constant insulating layers, reducing the capacitive coupling effect inside the chip, reducing signal transmission delay, and improving the operating speed and performance of the chip. In addition, mesoporous materials can also be used to prepare heat - dissipation materials for electronic devices. Their high specific surface area and good thermal conductivity help to improve the heat - dissipation efficiency, ensuring the stable operation of electronic devices in high - temperature environments.BMN Film Voltage - Controlled Dielectric Varactor j. Optical MaterialsMesoporous materials can be used to prepare optical waveguides, luminescent materials, etc. in the optical field. By doping luminescent rare - earth ions or organic luminescent molecules in mesoporous materials, the luminescent properties can be regulated to prepare high - efficiency luminescent materials. The mesoporous structure can also regulate the propagation of light and is used to prepare optical waveguide devices with special optical properties, which have potential applications in optical communication and optical information processing.

Learn more